About us

LEVEL OF PERFORMANCE

The Wilhelmsburg Tank Farm provides extensive services for the storage and handling of mineral oils, biogenic liquids and many other special products.

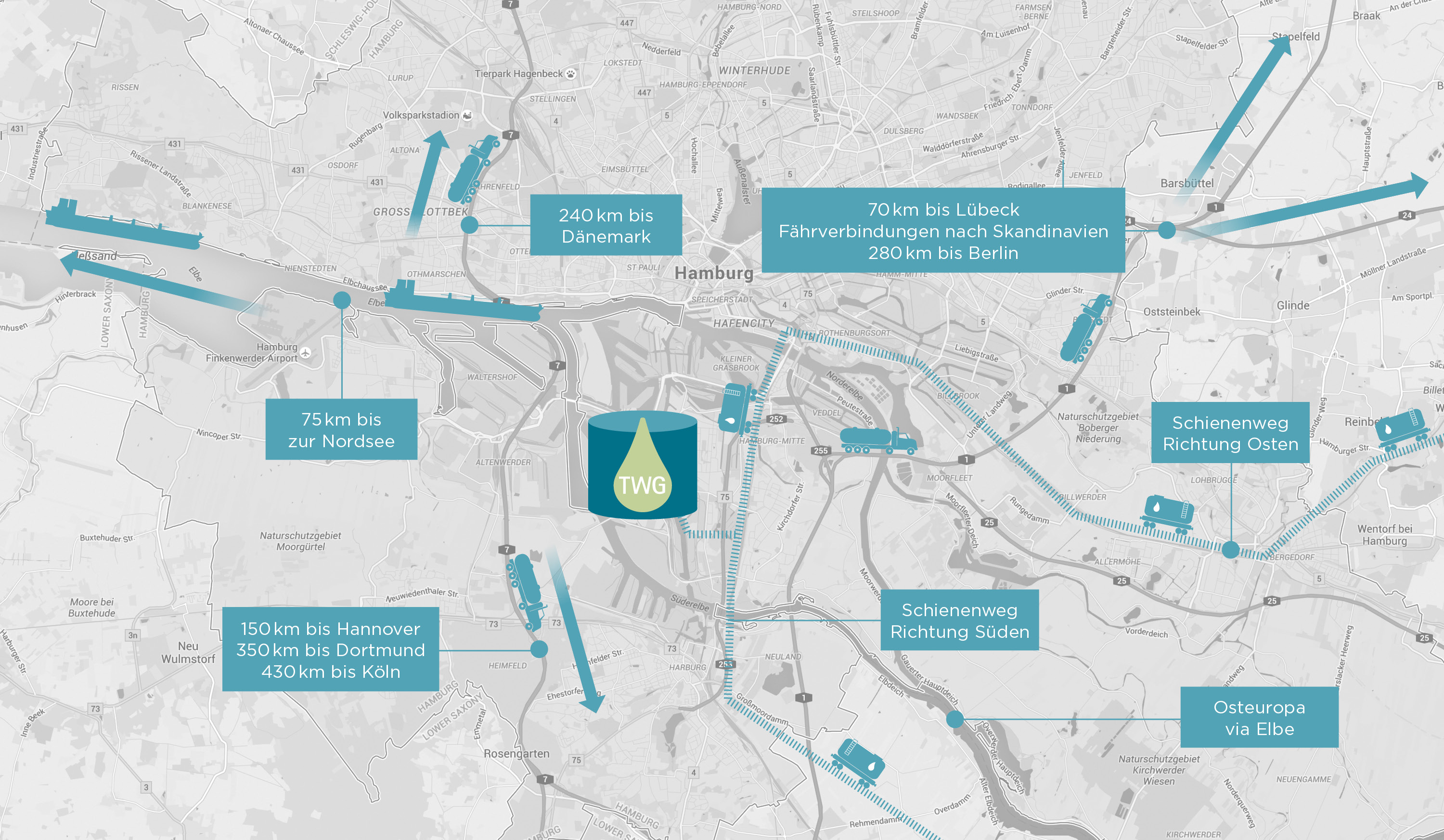

ADVANTAGE OF LOCATION

Hamburg is home to the largest sea port in Germany and the third-largest in Europe (2015) and offers excellent transport connections. The tank farm can be reached by water with sea-going vessels (up to 9 meters draft) and by barges – shipping routes connect the Port of Hamburg with more than 900 ports in more than 170 countries. The tank farm can also be accessed with rail tank cars and road tankers.

FLEXIBILITY

Our 22 tanks can be used in combination with one another or isolated as single tanks. We provide the ideal equipment and the necessary flexibility for your needs.

SERVICE

We are available for you from Monday to Thursday from 7 a.m. to 6 p.m. and on Fridays from 7 a.m. to 3 p.m. If necessary, for example for sea-going vessel stevedoring, we also offer our services outside of those hours. We will gladly send you an offer for extending or retrofitting the storage system. The tank farm provides its services with certified quality management in accordance with ISO 9001:2015.

QUALITY POLICY

TWG Tanklager Wilhelmsburg GmbH recognizes the responsibility for quality assurance, health protection and accident prevention as well as environmental protection as an integral part of its management function. The company sees this as its primary responsibility and the implementation of appropriate quality standards as key to successful corporate management.

The quality policy requires continuous improvement of quality assurance activities and the company therefore manages its corporate activities according to the following principles:

The company undertakes to,

- comply with all relevant laws and regulations

- adopt a policy of continuous improvement and make the best use of its management resources in quality management matters

- to disclose its quality management objectives and its performance against these objectives both within the company and to the customer and all interested parties

- ensure that its activities are safe for employees, partner companies, suppliers and subcontractors (external consultants) or other persons with whom it comes into contact in the course of providing its services (occupational health and safety)

- to cooperate closely with its customers and suppliers with the aim of achieving the highest quality standards

- adopt a forward-looking attitude with regard to future business decisions which may affect quality management

- to train its employees thoroughly in the requirements and responsibilities of quality management

It is the goal of TWG Tanklager Wilhelmsburg GmbH to meet and exceed the expectations of customers, employees and investors by involving and motivating all employees and implementing a properly documented quality management system according to ISO 9001:2015 .

QUALITY TARGETS

- Highest customer satisfaction has top priority

- Deviation-free services

- Optimal employee satisfaction through the involvement of people, i.e. employees

THE TANK FARM WILHELMSBURG BY THE NUMBERS

Our Equipment

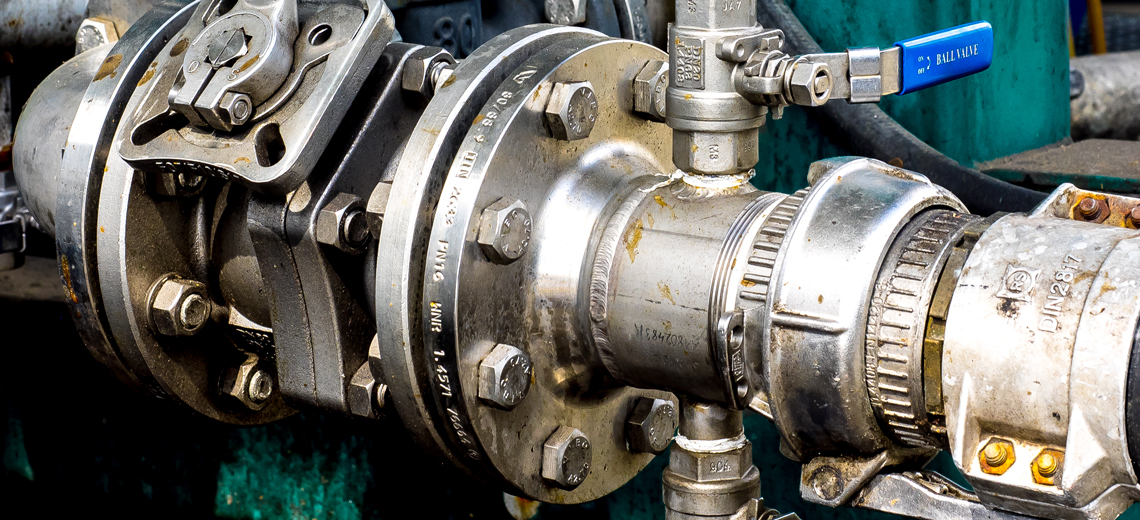

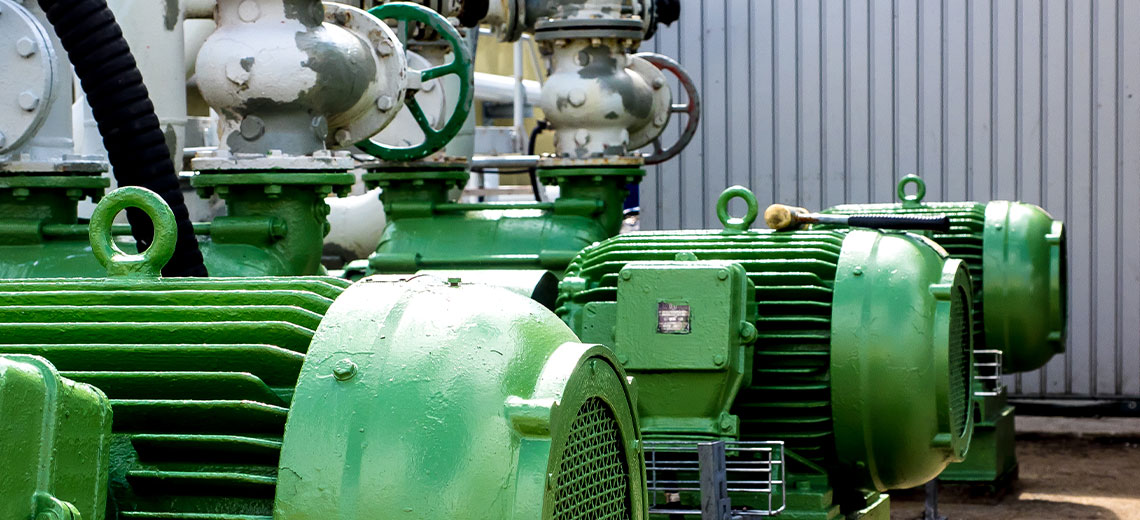

The equipment of the Wilhelmsburg Tank Farm meets the most demanding standards. Today’s requirements in the areas of facility safety as well as environmental protection and employee health and safety are very important to us and are met with the most modern technology.

We have continuously updated and expanded our equipment since 2007 – for example with new electrical, measuring and control technologies, modern vehicle scales, new filling stations and new piping. The tank farm also includes modernized office and team buildings with a control room.

Accessibility

We possess a total tank volume of approximately 74,000 cubic meters and offer flexible storage and discharge options. The trimodal accessibility is of high significance – the tank farm is accessible by water, rail and road. Therefore Hamburg's existing expansive logistical network with many national and international connections can be used in several different ways.

Ships

The tank farm is currently connected to the sea-going vessel and barge dock of the neighboring company Halterman Carless through 3 separate transfer lines. The loading and discharge capacities currently reach up to 300 t/h, depending on the product. The dock is suitable for sea-going vessels up to 230 meters in length with a draft of 9 meters as well as for barges.

Rail

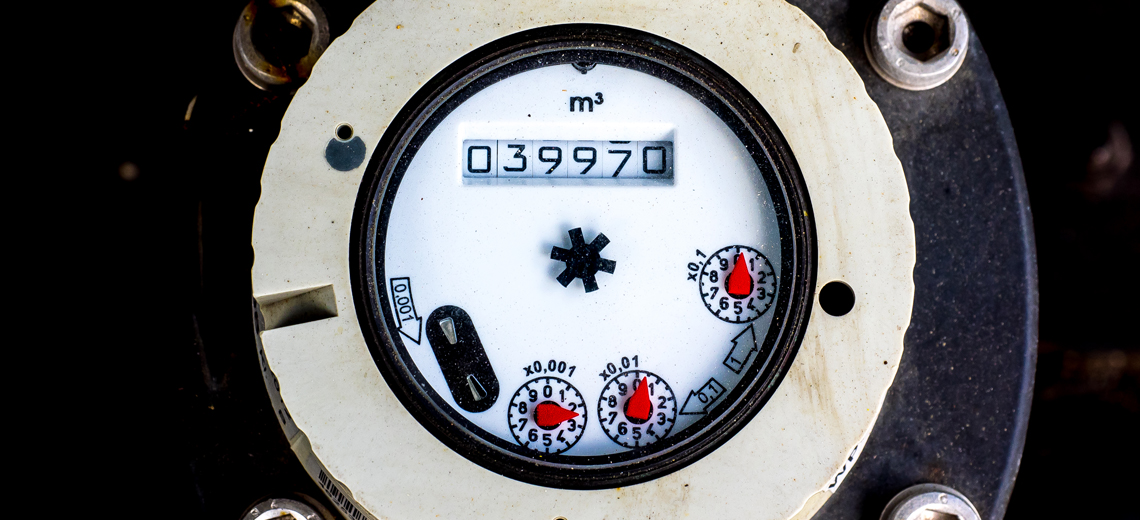

The loading and unloading of rail tank cars is carried out on a calibrated scale on our premises. The rail facilities allow for a train length of approximately 100 meters. Block trains can be served by dividing the train into several sections on the transfer track of the port railway. The transfer track is located immediately outside the tank farm site.

Road

Tank trucks and containers are loaded and discharged at 2 filling stations using the bottom loading process. When discharging, the pump of the tank truck is used or it is emptied by air pressure. A calibrated scale is used for exact determination of the mass. For loading normed diesel fuel, we provide a calibrated volumetric measuring section with loading arm (DN 100).

Our products

The Wilhelmsburg Tank Farm („TWG“) is an approved storage facility for flammable mineral oil products (diesel, heating oil etc.), biodiesel, vegetable oils, liquid fertilizers and other special products (liquid latex, salt solutions etc.). In addition, TWG is registered as a bonded energy tax warehouse and is also an approved fuel dyeing operation (dyeing of fuels to be transported by ship is currently not possible). Our participation in the European EMCS-process guarantees flawless customs processing of the logistical requirements. In the following, you will find a selection of the products we can process:

Mineral oils

- norm diesel

- ship diesel

- heating oil

- bunker oil

Vegetable oils and ester

- rapeseed oil

- soy oil

- sunflower oil

- biodiesel

Water-based solutions

- liquid fertilizer (AHL)

- salt solutions (e.g. calcium nitrate)

Special products

- liquid latex

- fatty alcohols

Technical Data

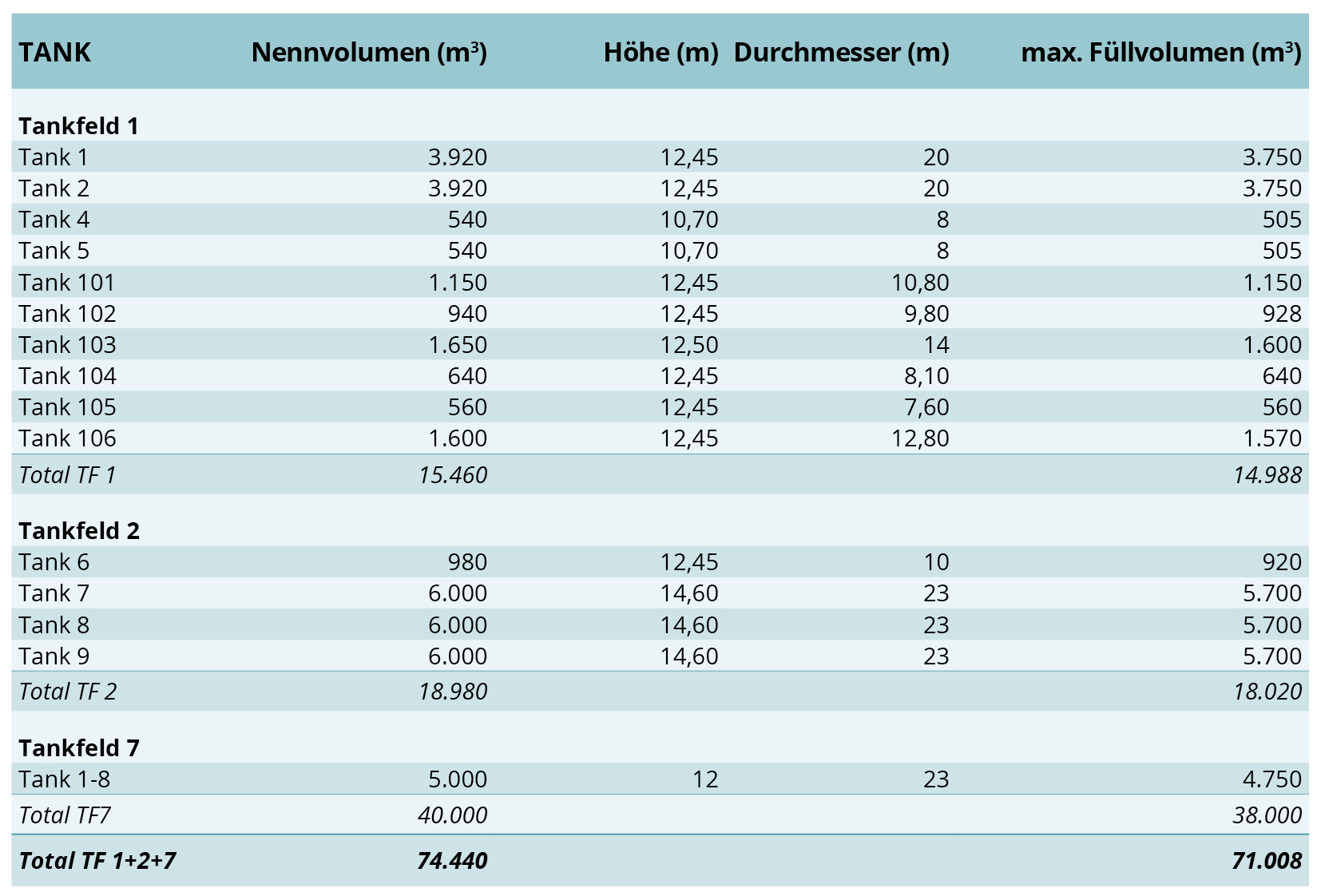

The Wilhelmsburg tank farm currently has 22 tanks, 14 of which with a total nominal volume of approx. 35,000 m³ are operated in tank fields 1 and 2. These tanks have nominal capacities of 500 m³ to 6,000 m³. 8 tanks with 5,000 m³ each (total nominal volume 40,000 m³) in tank field 7 will probably be available from 2024 after a major overhaul.

All tanks are made of carbon steel. Loading and discharge lines are in part made of stainless steel. Some tanks are lined with epoxy resin on the inside, heated with warm water and insulated. Each tank has a separate pump for discharge. Some lines are equipped with a mixer jet for blending two liquids or with an additive device, for example for dyeing mineral oil.

A high-performance monitoring system controls the operation of the tank farm. Our tank farm is equipped with all the necessary systems in order to guarantee safe operation and prevent environmental damage.